A good flush is important for any boat or PWC, especially if you ride in saltwater. Even in freshwater, like a lake, it’s still a good idea to flush your PWC once in a while.

It’s just that saltwater is vastly more important that you flush. So, before we get into the steps of flushing PWCs, we need to cover where you ride.

Where Do You ride?

Where you ride your PWC affects when you should flush the engine and exhaust, as well as the specific steps involved in the flushing process.

Saltwater

If you ride your PWC in saltwater or any dirty water, I suggest you flush after every ride or at the end of the riding day!!! It’s the standard for most boats that go in saltwater.

Once you’re done riding the PWC for the day, you need to hook up to a clean freshwater supply and flushing it. (Clean water, as in tap water)

Fresh Water

If you ride your PWC in the lake or fresh water, flushing after every ride is not necessary.

It won’t hurt flushing after every ride if you like, especially if you’re going to clean it after every ride, but it’s not the end of the world if you don’t do it after a freshwater ride. (The average PWC owner goes months not flushing their engine, if they only ride in fresh water)

Important:

- Never flush hot engines, allow it to cool down for at least 30 minutes.

- Only flush for the maximum of 90 seconds.

- Start the engine before turning on the water.

- Turn off the water before shutting off the engine.

Key Points:

The Reason for flushing Your PWC

There’s a joke that “the two worst things for your boat are sun and water” it’s funny because it’s true. The reason you flush the engine and exhaust is that saltwater is highly corrosive, and can damage metal and moving parts.

Even freshwater can be corrosive, though saltwater is 100X worse, so freshwater often gets overlooked.

For preventing damage on your PWC, mist engine compartment and pump area after flushing and avoid leaving the machine in water for long periods.

Using drive-up PWC dock or lift works best.

Jet Ski Flushing Steps

Flushing is simple, but there are some important steps you must do to avoid hydrolocking your engine.

These steps for flushing are best shown in a video like the one below.

Flushing In Freshwater

If you want a simple way for flushing the vital compartments, you can always take it on short rides in freshwater, NOT saltwater.

The flush with your garden hose will be the best way, but it has its risks if you do the order wrong.

So, if you’re unsure, a quick ride in freshwater is a super easy way to do it.

Mist The Engine Compartment!

After saltwater rides, you should flush and also mist the engine compartment and rinse the pump area of your watercraft.

Make sure to remove the drain plugs when cleaning a engine compartment, and then put them back in before you ride!

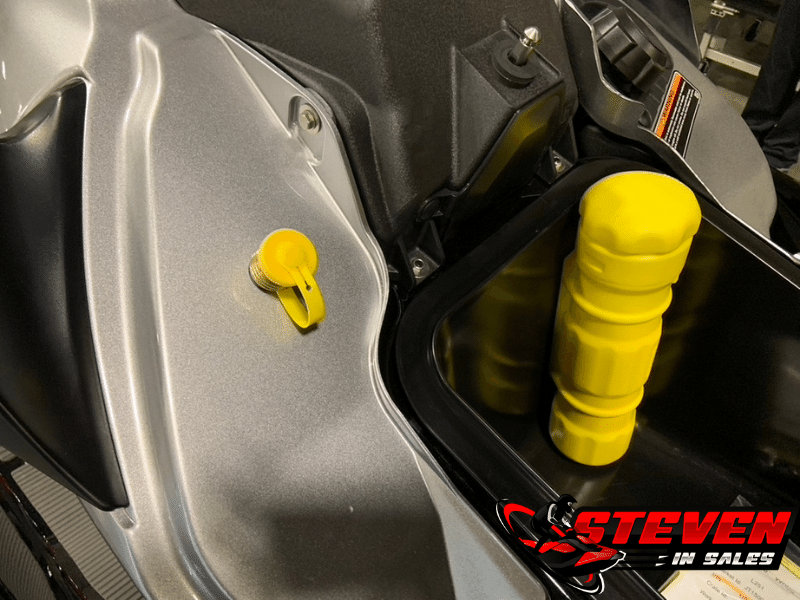

If you have trouble removing the drain plug on a modern Sea-Doo, then consider getting this wrench.

Tip: Once a month, I suggest spraying “silicone lubricant (Amazon Link Ad)” on the engine and pump area, anything metal, electrical or shiny. You should do this for sure if you ride the PWC in saltwater, but if you ride in freshwater, you can do it at the start and end of the riding season.

Failure To Flush PWCs

Failure to flush a PWC will lead to metal parts corroding and even phantom electrical problems down the line.

The picture below shows the PWC that was not properly flushed or maintained after numerous rides in saltwater.

As a result, it suffered extensive corrosion damage.

The deterioration was so severe that the green antifreeze in the ride plate began to leak through the corrosion holes.

The jet pump is made of mostly metal, and while it’s painted, corrosion still gets it. This is why the rinse off with the garden hose is so important. Just an engine flushing is not always enough, other parts of the jet ski body need flushing of freshwater.

Stopping Corrosion on your jet ski

Keeping your jet ski in great condition, especially after riding in saltwater, is simpler than you might think.

The best approach would be the flushing and rinse the jet ski off after every saltwater ride. This really helps in preventing corrosion.

Did you know that jet ski manufacturers include something called “sacrificial anode” in their designs? It’s the clever little part that’s designed for corroding first, protecting the other metals. But it’s important to keep an eye on this anode tucked away in your jet ski. Regularly check to make sure it’s still there and in good shape. If it looks worn out or damaged, it’s time to replace it.

Typically, there are one or two sacrificial anodes on most jet skis, and you’ll find them near the jet pump. You won’t find any in the engine compartment, so it’s good practice spraying this area with silicone lubricant for extra protection.

Taking these small steps can really extend the life and performance of your jet ski.

Don’t Forget Rinsing The jet ski Trailer!

When you’re rinsing your jet ski with the garden hose, make sure you rinse the trailer as well. Even if the trailer is made from aluminum or galvanized metal, it still has steel parts, like bolts, screws, and other hardware, that can rust over time.

Saltwater especially speeds up corrosion, so it’s important giving the trailer thorough rinse after every saltwater ride. Even if you only use it in freshwater, it’s still smart practice rinse it occasionally.

Pay extra attention around the bolts and nuts. They might not be aluminum or stainless steel, and they’re usually the first parts that rust. It might sound minor, but I’ve seen bolts on aluminum trailers completely eaten away by corrosion. Simple rinse/flush can make significant difference and keep your jet ski trailer from literally falling apart.